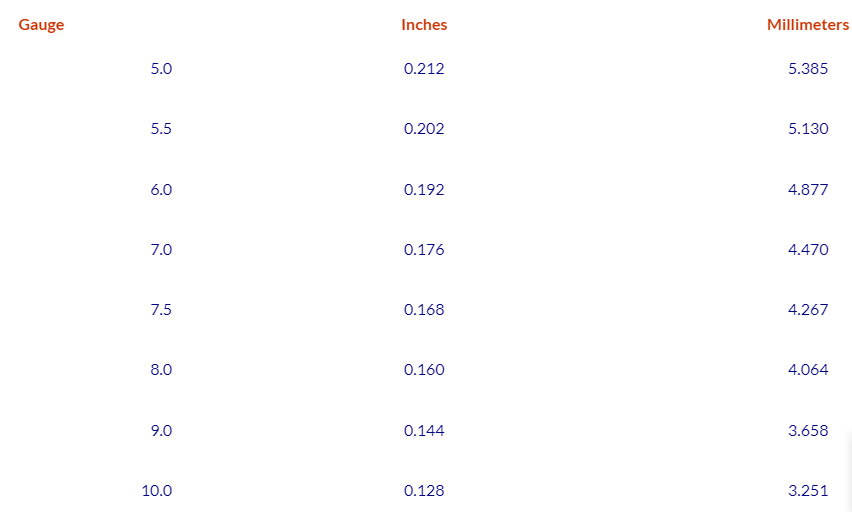

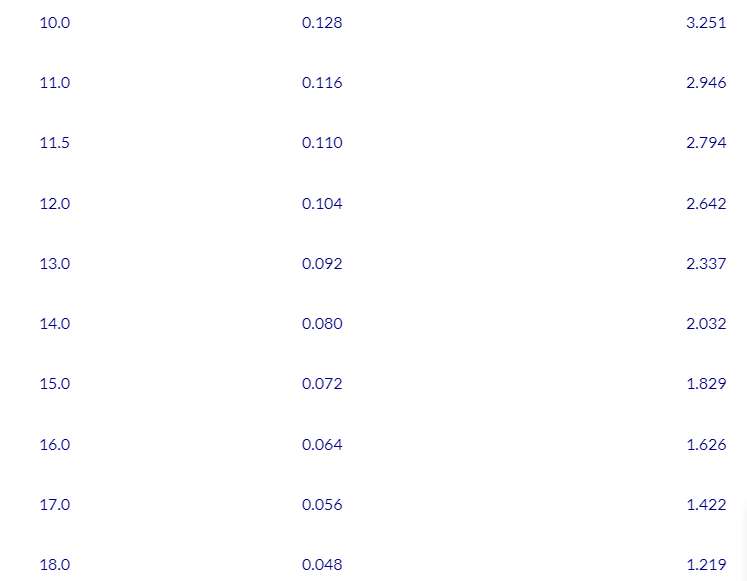

A higher gauge number means a smaller needle diameter. For example, a 20 Gauge needle’s diameter is less than a 10-gauge needle’s diameter. Here are the U.S. and metric diameters for needle gauges:

The thickness of the needle.

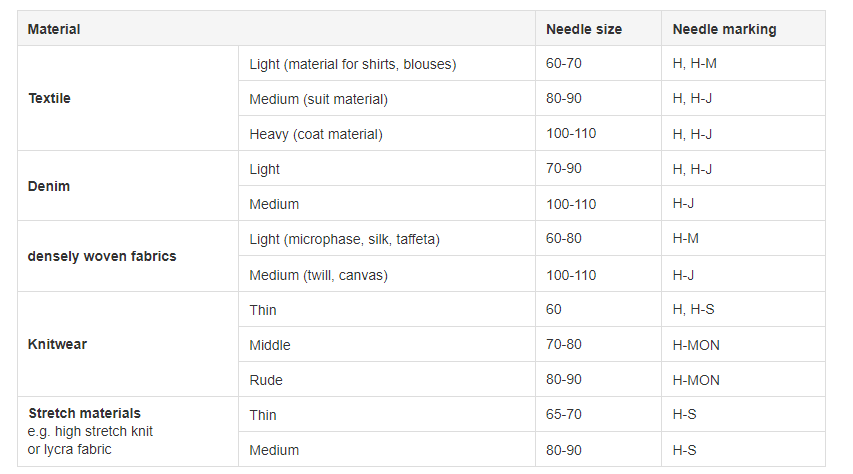

Naturally, this is the main parameter. The thicker the fabric, the thicker the needle should be. The main sizes of universal needles for household machines in the metric system are 60, 70, 80, 90, 100, 110, 120. A needle for knitwear has, in general, a thickness of not 70, but 75.

For convenience, a serial number is often used. Usually, it is indicated through a fraction of the metric size.

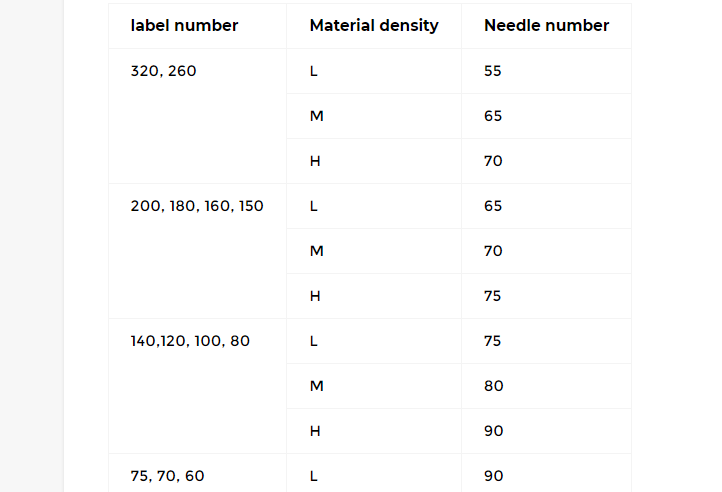

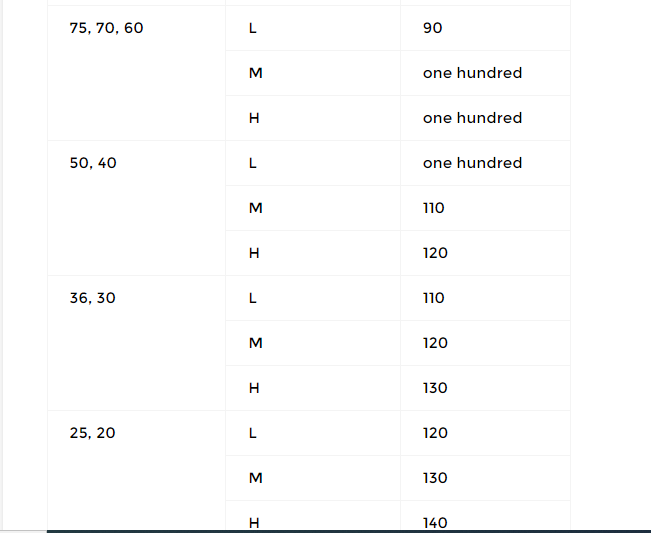

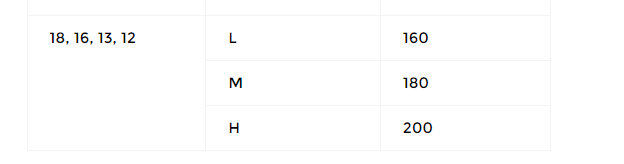

In order to make it easier to navigate in the variety of needles, we give a separate plate:

Needle size is critical when material damage occurs. A needle that is too large can break the structural threads of the fabric or cause tension in the stitch area, resulting in holes that are too large. For this reason, you should use the thinnest possible needle that allows you to work with the thread you need. However, you should also take into account the significant fluctuations of thinner needles at high sewing speeds, which can lead to frequent needle breakage.

The density of the material is also important. For a general understanding, below is a table of a recommendatory nature, illustrating the correspondence of the size of the needle to the thickness of the thread and the density of the material. Explanation of fabric density designations (conditionally): L – light (up to 200 g / m²), M – medium (200-300 g / m²), H – heavy (over 300 g / m²).

Sewing machine needles – needle types and designations

What do the letters on the needle packaging mean?

A package of sewing machine needles contains information about the needle system and needle type, e.g. 130/705H-J for jeans needles.

The designation 130/705 describes the needle system. The 130/705 needle system is the widespread standard and is used on all household sewing machines.

The following overview shows the meaning of the letters at the end of the designation.

H = scarf shape

HE = embroidery needle

HJ = jeans

HM = Microtex

HQ = quilting needle

HS = stretch

H-LL = leather

H-SUK = medium ballpoint (stretch/jersey)

H-ZWI = twin needle

H-DRI = triple needle

MET = for metallic yarn

H-WING = wing needle for hemstitch

H-SPR = spring needle

Needle sizes and their importance

The indication of the needle size refers to the diameter of the sewing machine needle. The following applies: the lower the number, the thinner the sewing machine needle and the thinner the fabric to be sewn.

The needle size is always specified as a combination of the German and American dimensions, e.g. 70/9 for a 70 sewing machine needle. The needle size is given in 1/100mm. A sewing machine needle size 70 corresponds to a needle size of 0.7 mm.

Overview of the most common needle types

Universal needle 130-705H

The universal needle is suitable for all normal sewing work and has a slightly rounded needle point.

The strengths of this sewing machine needle range from 60NM to 120NM.

Jeans needle 130-705H-J

The jeans needle is particularly sharp and has a reinforced shaft. A denim needle has a blue color marking on the shank.

The strengths of this sewing machine needle range from 70NM to 110NM.

Jersey needle 130-705H-SUK

The jersey needle has a round needlepoint and pushes the fabric aside when sewing without damaging it.

The strengths of this sewing machine needle range from 70NM to 100NM.

Stretch/SuperStretch 130-705H-S

The stretch needle has a semicircular ball point and is suitable for particularly stretchy fabrics. A stretch needle has a yellow marking on the plunger.

The strengths of this sewing machine needle range from 65NM to 90NM.

The basic function of a needle

- Create a passage for the thread through the fabric.

- Pass the needle thread through the material and form a loop that will be picked up by the hook or looper mechanism.

- Pass the needle thread through the loop made by the looper mechanism (on machines that do not sew with lockstitch).

The needle structure

A needle consists of different parts that can be used to perform the following different sewing operations:

- Plunger Face

The shaped upper end facilitates the insertion of the needle into the needle holder. - Butt

The thicker part of the needle is held by the needle clamp or needle locking screw. It supports the needle as a whole by giving it extra strength. - Taper

The middle part is between the piston and the skirt. - Shaft

The portion of the needle that extends from the butt to the eye. This is exposed to the highest friction and thus heat when it pierces through the material. - Long Groove(s)

Located on one side of the needle shaft to better collect the needle thread from the take-up device and provide a protective channel for the thread to be drawn down through the material during stitch formation. - Short Groove

It is formed on the other side of the long groove toward the shuttle, hook, or looper mechanism and helps form the loop of the needle thread. - Eye

The eye is located at the bottom of the shaft. The needle thread that is passed through the eye is guided to the lower part. - Fuller (opening)

An opening in the shank above the eye to allow for tighter adjustment of the shuttle, hook or claw mechanism. - Point

The point of the needle is shaped to best penetrate the material to be sewn and create the desired stitch effect. - Needle tip

The shape of the needle tip determines the piercing performance. - Other Variants

Most needles that are manufactured have these parts. However, there are some exceptions. Some are designed to overcome certain sewing problems or simply to meet sewing machine requirements.

Recent Posts

There are several reasons why your sewing machine needle is not moving.Make sure the machine and the foot pedal are securely plugged in.The bobbin case is not installed correctly in the...

Use a size 80 universal needle ( it sale here) and a medium stitch length of 2.5 mm. For stretch velvet please use a jersey needle.Choose a needle based on the thickness and heaviness of the...